Gould Memorial Library

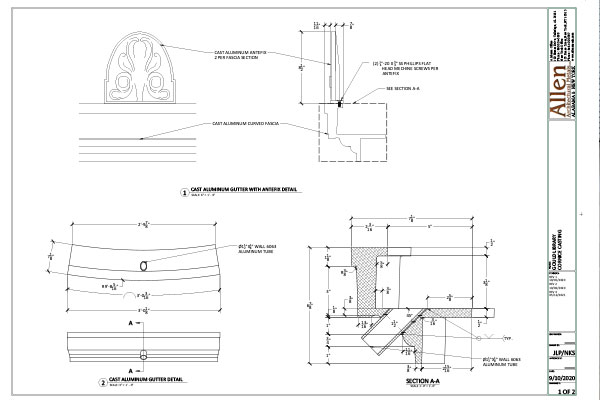

The restoration of Gould Memorial Library required the replication of architectural metal elements at the cupola dome, including the antefix and gutter assemblies. Originally fabricated in copper sheet metal, these components had suffered from distortion and material fatigue over time, compromising both performance and long-term durability.

In accordance with the project specifications prepared by Nicholson and Galloway, Allen Architectural Metals replicated the historic profiles using cast aluminum, preserving the original design intent while improving structural stability and longevity. The project was recognized with a Lucy G. Moses Preservation Award in 2024.

Scope of Work

- Replication of historic antefix elements in cast aluminum

- Recreation of the existing copper sheet metal gutter system in cast aluminum

- Custom pattern making and reverse engineering

- 3D modeling of curved gutter profiles to follow the cupola radius

- Fabrication of custom aluminum downspout fittings

- Machining of select gutter castings

- Custom color matching and coating to replicate historic green patina

Material Strategy

Although the original antefix and gutter elements were fabricated from copper sheet metal, the contract specifications required new aluminum castings to match the existing profiles and dimensions.

The original copper components provided for reference were found to be warped and insufficiently rigid to accurately capture the intended geometry. To resolve this, Allen Architectural Metals requested additional samples with structural backing to ensure dimensional fidelity during reverse engineering.

Using these references, the AAM pattern shop produced clay molds from the historic antefix elements, which were then used to create accurate patterns for aluminum casting.

Technical Approach

- Clay molds were produced directly from historic antefix elements

- Profile molds were taken from existing gutter sections

- Gutter assemblies were digitally modeled to ensure accurate curvature

- Backside geometry was modified to accommodate new mounting substrates

- Select gutter castings were machined to receive custom aluminum downspout fittings

- Downspout fittings were fabricated and shop-mounted for alignment and fit

This approach allowed the cast aluminum assemblies to maintain the visual character of the original copper sheet metal while meeting modern performance requirements.

Finish and Color Matching

To preserve the historic appearance of the cupola, Allen Metals collaborated with Tnemec to develop a custom color match replicating the green patina of the original copper elements.

Preservation Considerations

The project reflects accepted preservation practice by:

- Maintaining historic profiles and proportions

- Replicating original elements in a compatible, durable material

- Documenting material transitions

- Preserving visual continuity while improving performance

By combining traditional pattern making with contemporary modeling and fabrication techniques, Allen Metals delivered a solution aligned with preservation standards and review expectations. The restored cupola elements now provide improved structural integrity, long-term durability, and visual continuity with the original design.

Details

LOCATION

Bronx, New York

ARCHITECT

Beyer Blinder Belle

CONTRACTOR

Nicholson & Galloway

MARKETS

METALS